Design Evolution

Professor of Architecture Kyoung Hee Kim began developing microalgae-filled building façade systems years ago, prompted by an environmental science class in graduate school. Knowing algae’s ability to sequester carbon and improve air quality as well as potential uses as food or energy sources, she began to design window installations in which microalgae could grow.

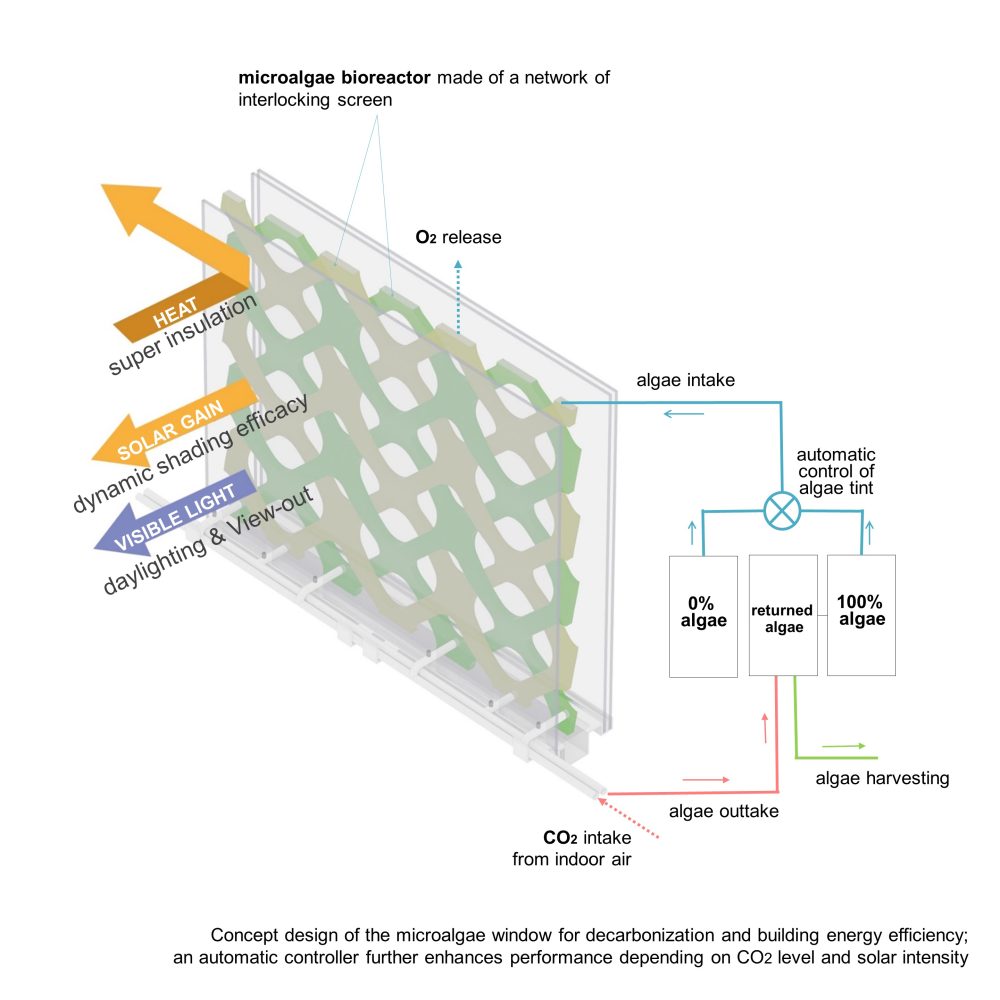

The algae’s greens and blues provide shading from the sun, and a pump circulates air through the system, filtering out carbon dioxide and impurities and releasing fresh, oxygen-rich air. Periodically, the algae can be harvested for other uses, such as biodiesel fuel.

Kim and a team of student researchers began prototyping in 2011. Over the years, the work has been funded by several different grants from the National Science Foundation and the American Institute of Architects. As she has learned from her successes and failures, the architectural design of Kim’s installation has evolved dramatically, resulting in three distinct typologies. Currently, Kim has an installation at the Innovation Barn in uptown Charlotte, where she and her team have been testing its performance for six months and are continuing to make improvements.

“Design, make, operate and validate. Those are the key steps that have been occurring throughout the different typologies,” Kim says. “I just have been very curious. What if I do this?”

Here, Kim explains the development of each design.

Design 1: The Interlocking or X Module Prototype

When I design a system, I often think about either a design motif that inspires me or symbolic meanings. So, as you may tell from the word “interlocking,” I was very interested in how to make humans and algae coexist in a space, and I thought creating an interlocking structure can communicate my design intent.

When I am thinking about design, I’m also thinking about functionalities. Throughout all the processes since 2011, my design process has consistently been guided by three perspectives —human, microalgae, and building. Design criteria from the human perspective were view out and daylight – whether I have a place to view out and let the daylight in to the space.

And the second function from the microalgae perspective is that it has the right cultivating environments to grow. I need to have a good amount of solar exposure, and I need to also provide air into the system. From the building perspective, the system should contribute to building energy efficiency, control of sunlight/solar gain, and biomass harvesting.

I’m thinking about symbiotic relationships. Humans produce biogenic carbon dioxide, and then algae can use that waste from humans for their nutrients. And in return, algae produce oxygen, and humans use oxygen for our benefit. I need to incorporate the inlet of the air, which will be at the bottom, because air rises. And then I’m going to put the outlet of oxygen and clean air from the top.

And then, for the cultivation of microalgae, I am bringing the young algae in from the top and incorporating the algae harvesting outlet at the bottom. So those are four outlets. And that hasn’t changed as different typologies evolved.

You also may notice it’s not a planar X. It’s a three-dimensional X. The angle could be adjusted to solar angles. So, if I install in, let’s say, Miami, Florida, you may want to bend more, because the sunlight is always very steep. So we could adapt to different locations.

“Interlocking” won a 2021 R+D Award from Architect Magazine.

The design challenge: Modular units are good for adapting to different sizes of window and different shapes. But because of these modular pieces, I needed to deal with leak potentials in those joints.

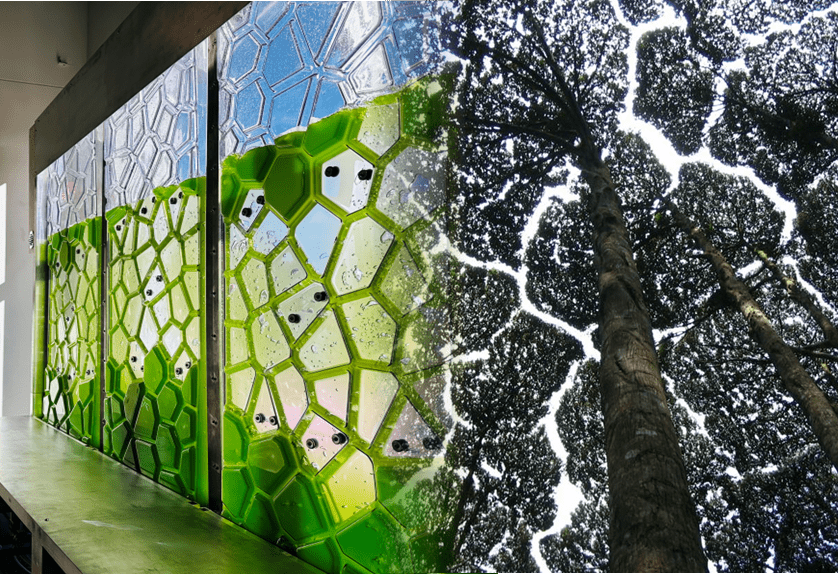

Design 2: Crownshyness

I was inspired by the crown shyness – the spacing in the canopy of trees. If you look up, you see that the crowns yield a little bit to each other. They create a gap to let the daylight in and also to prevent the potential spread of disease. There is a self protection through this, and also an altruistic behavior for other little vegetation below.

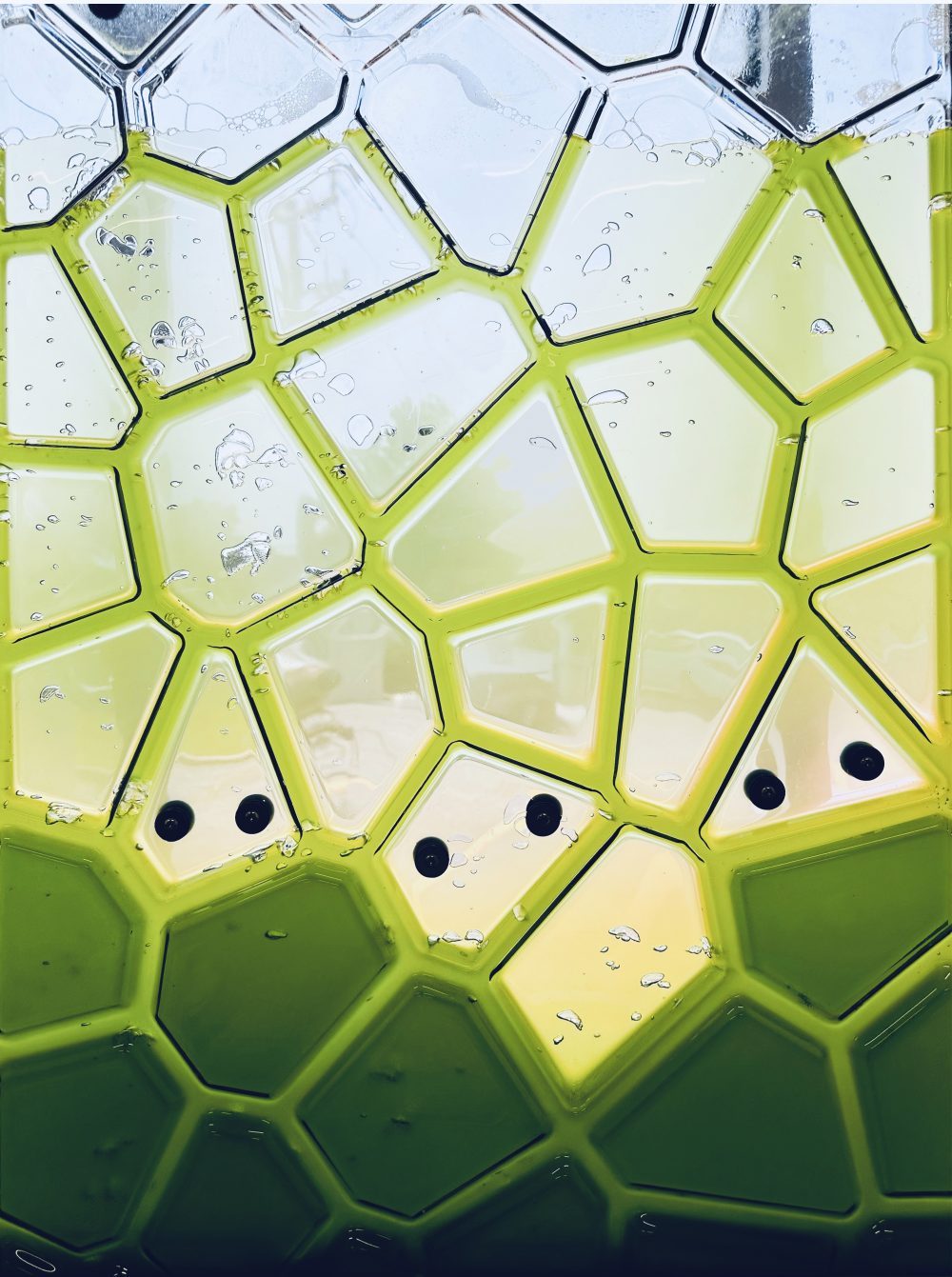

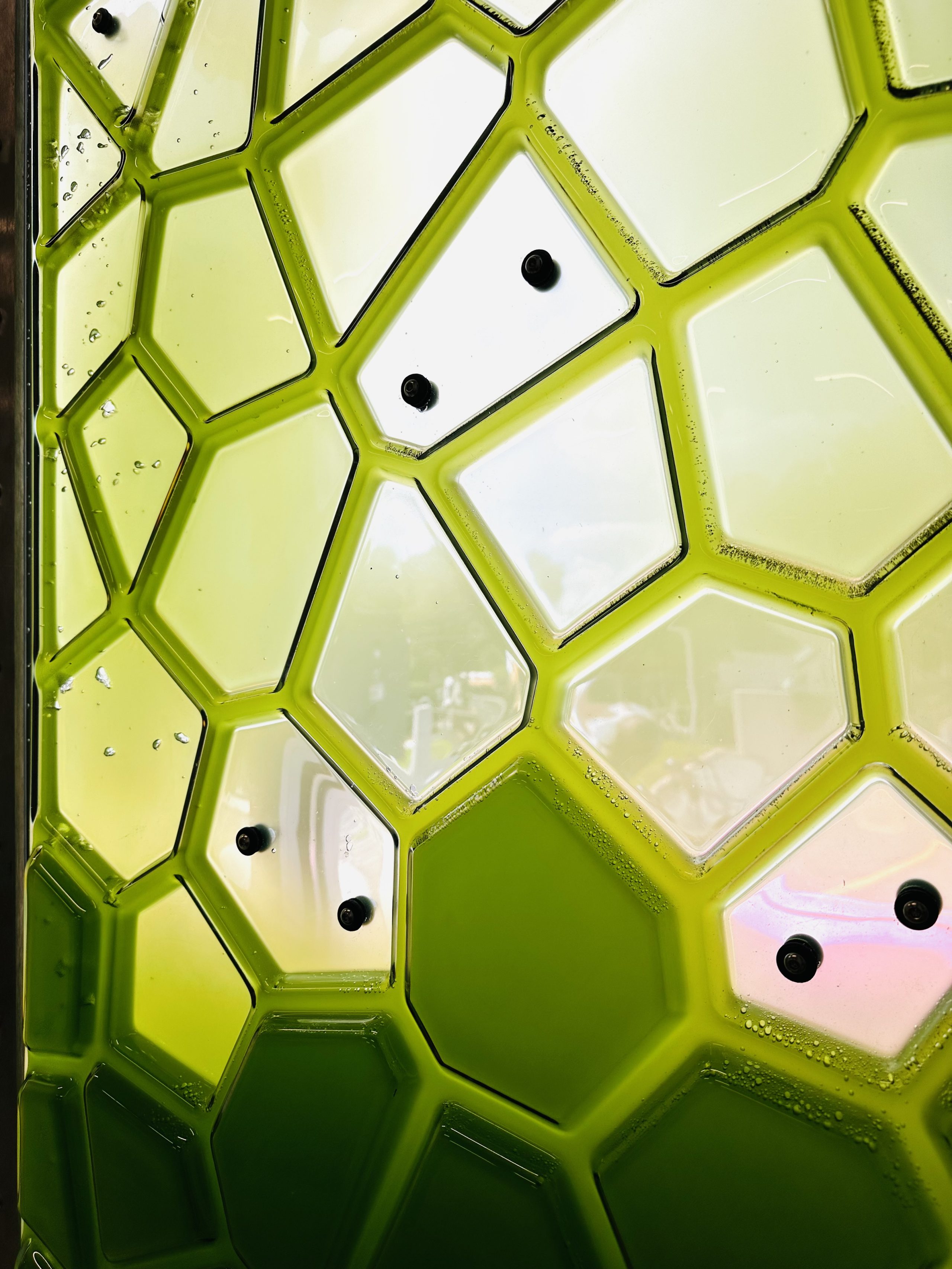

With this design, I still need to provide transparency at human eye level, to create a view out. For the microalgae, the system needs to provide a good growing environment with adequate light and air circulation. So the top and bottom of the panel are thicker, for growing more microalgae, and the middle is much thinner and transparent/translucent, for the viewing experience.

To create those view-out zones, the original intent was ultrasonic welding, which needs specialized equipment, creating a very high pitch frequency to weld two polycarbonate pieces into one.

I was using half-inch thick polycarbonate. Two sheets would become just one sheet, a one-inch sheet of polycarbonate for the view-out zone. The intent was to find a manufacturer who could do ultrasonic welding for us, and we spoke to a few, but their machines were very small.

So mechanical connections (the bolts you see above) were introduced to hold two sheets together without bulging. But the original design intent was very clear: two sheets of polycarbonate combined into one piece.

“Crownshyness” won the Bronze Award for Product Design in the 2025 Design Educates Awards.

The design challenge: This design had no leak, but it was not up to our true design intent as far as the view out goes. And in order to create the crown shyness texture, it requires thermal forming. We apply the heat and then let the heated polycarbonate sit on top of the mold. But that process, in fact, creates a residual thermal stress to the textured panels, and eventually they become brittle.

“Those kinds of failure moments really make me pivot. That’s why we pivoted to the blade, the other typology.“

Design 3: Blades

We pivoted to an extrusion method to address the design challenge. It doesn’t induce stress brittleness during the manufacturing process.

This blade design is much simpler. If one blade goes wrong, I can replace it. With the big panels, if one panel becomes contaminated, I need to drain and refill the entire panel again. It’s such a big waste. So, in terms of the operation and maintenance, this has been the best so far.

The nice thing, too, about the blade is that it is able to rotate, depending on what light level the algae need. And then, in the meantime, between the blades I can create a totally clear view out, if I make the blades all 90 degrees perpendicular to window. If I need privacy, I can also close it off, so no one can see from outside into the space.

“The algae are growing well. And they’re also performing air purification. It proved to be as we hypothesized.“

Of course, there are many areas that I am still working on. For example, I want to incorporate artificial light. Light is not only good for enriching the human experience, but also I can use it to supplement lighting for growing algae on cloudy days. We are working on a new cap design with a waterproofing pocket to install the LED light while allowing the light to project into blade.

The automatic nutrient dispenser is another area I’m working on. At the moment I go to the Innovation Barn every other week with two buckets to give nutrients for the algae. But I can automate the nutrient dose.

I’m also incorporating the automatic biomass sensor in the system and exploring AI integration as well. For example, if I want to grow a certain algae species – let’s say Nannochloropsis for biodiesel production, which is different from Spirulina for food applications – I can incorporate AI to predict the best growing environment for that algae, depending on the dynamic environmental conditions.

So I am expanding more functionality to the operation and maintenance. I’m using this Innovation Barn installation to fully modify, develop and refine the system, hoping to be ready for a commercial setting.